Branch: JinLei Precision Machinery Co.,Ltd.

Mob: 13925415705 Angela

Mail: angela@jljmjx.com

Add:No.3,Haiyu 1st Rd.,Fuan industrial Zone,Leliu town,Shunde District,Foshan City,Guangdong Province,China.

What is the rubber machine

Home - 最近动态 - Industry information

Rubber machine is widely used in chemical industry, light industry, food, building materials, and other industry of solid - liquid, liquid - liquid phase materials mixing, reaction, was dissolved and scattered process, such as adhesives, silicone sealant, polyurethane adhesive, acrylic glue, automotive sealants, and plastic packaging, ointment and paste like materials, grease and paint, paste like cosmetics, ink and pigment and emulsion and paste food and additives of making this type of mixer can and various forms of production at the same time, single speed and double speed, speed, three speed can choose, meet all kinds of technical requirements.

Rubber machine is divided into closed and open

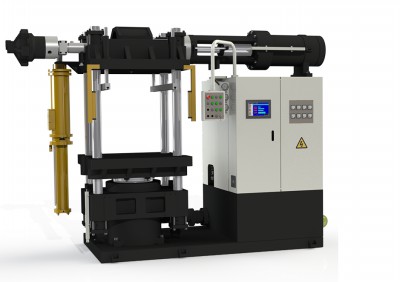

1, closed rubber machine

Is mainly used for rubber plastication and mixing. It is an open type mixer mixing chamber (Figure 1). Raw rubber and compound from a hopper into the mixing chamber after charging door closed, pressure feeding device on the top of the plug pressure, densely refining indoor two rotors with different or same opposite rotary speed. The loaded rubber in the rotor between the rotor and the mixing chamber between being stirred, folded and strong kneading effect, oxidative chain scission, increase the degree of plasticity. At the same time, glue due to shearing and dispersing and mixing, so as to achieve the purpose of mixing. Since 1916 invention elliptic rotor closed Lianjiao machine, closed mixing machine in rubber industry rapid development appeared, and then other forms of the rotor mixer. The mixer mixing cycle for 2.5~3 minutes, the maximum capacity of 650 liters mixer room.

, 2 open rubber machine

Is mainly used for thermal refining, rubber sheeting, gel breaking, plastication and mixing. It consists of a roller, a roller bearing, and distance adjusting device, emergency brake device, a frame, a base, a driving device and a heating and cooling system. Principle of open rubber mixing machine, rubber or plastic material between the two allometric opposite rotary roller with friction is pulled into the roll gap, the strong shear and compression to increase the degree of plasticity. This double roller open rubber mixing machine for production began in 1826. It has the advantages of simple structure, is widely used in modern.

You can choose a suitable rubber machine according to their actual needs. (you can also pay attention to: "press enter the outbreak period")